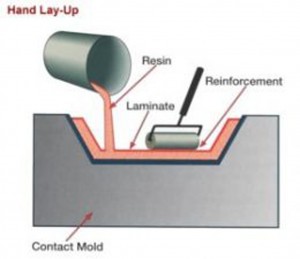

HAND LAY-UP OF FIBERGLASS PARTS ON A MOLD

1. PREPARING THE MOLD

Remove any dust and dirt from mold. If mold is of plaster, wood, or new fiberglass, apply soft wax and

buff with soft towel. Spray or brush with PVA, parting compound and allow to dry. If mold material is

glass, metal, ceramic, or well-cured fiberglass, apply three coats of hard wax, carnauba type, buffing

between each coat.

2. APPLYING THE GEL-COAT

1. If gel-coat is to be brushed on, allow first coat to cure and then apply the second coat to make

sure there are no light spots.

2. If gel-coat is to be sprayed on with a gel-coat gun, spray up to a thickness of .015” to 020”.

When gel-coat has cured long enough that your fingernail cannot easily scrape it free (test at edge

of mold where damage will not show on part) then proceed with next step.

3. LAY-UP SKIN COAT

Cut ¾ or 1 oz. mat to cover part. Brush catalyzed resin over gel-coat, then apply the mat. Work with roller

adding more resin where necessary until all white areas in mat fibers have disappeared and all air bubbles

have escaped. Resin-rich areas weaken the part. Where rollers will not reach, brushes must be used.

When this step is complete, clean all tools in acetone. Allow skin coat to cure before next step.

4. LAYING FIBERGLASS REINFORCEMENT

For a 12 ft. boat, two layers of 1½ oz. or 2 oz. mat may be adequate, depending upon design. For a 14 ft.

boat, an additional layer of woven roving will add considerable strength. Apply each layer as in step 3, but

it will not be necessary to wait for curing between these layers. Be sure to shake all acetone out of brushes

and rollers before applying resin. Acetone drips can result in uncured spots in the lay-up.

5. TRIM

On a small lay-up, the fiberglass laminate which hangs over the edge of the mold can be trimmed off easily

with a razor knife if you catch the “trim stage,” of the period after the lay-up has gelled but before it has

hardened. On a larger lay-up, it can be trimmed with a saber saw and coarse sand paper.

6. CURE

May take from two hours to overnight, depending upon turnover desired, temperature, canalization, and

nature of the part. If laid up in a female mold, longer cure will affect shrinkage and easier parting. In the

case of the male mold, the part comes off more easily before it shrinks appreciably. If the part is subject to

warping, a longer cure may be necessary. In any case, when the part is removed it should be supported in

its desired shape until fully cured.

7. REMOVE PART FROM MOLD

First, examine the trim edge all the way around the mold and make sure there is no resin bridging the line

between the mold and the part. Sand this edge where necessary. Then wooden wedges, such as “tongue

sticks,” can be pushed into the edges to start the separation. Continue separation by pulling and flexing. In

some cases it is necessary to drill a small hole in the mold and apply air or water pressure.

8. FINISH

Trim edges and back of part may need to be fine-sanded and coated with surfacing resin or gel coat.