FRP Vacuum Infusion Process Pump, FRP Vacuum Infusion Process Machine,Fiberglass Vacuum Infusion Process Machine

Resin Vacuum Infusion, Process for Manufacturing High Performance Composite Parts

FRP Vacuum Infusion Process Pumpfor Resin vacuum infusion is a cost effective process for making high quality fiberglass and composite parts. For many applications, parts manufactured using the resin vacuum infusion process have higher quality, better consistency, higher glass content, higher specific strength, higher specific stiffness, better interior finish, faster cycle time and lower cost compared to the open mold process.

-

Model No.

Vacuum Capacity

(L)

Pumping Speed

(m3/h)

Extreme Vacuum Degree

(-kpa)

Motor Power

(KW)

Suction Diameter

Weight

(Kg)

Outer Size

(meter)

LC-XD-020

65

20

101.3

0.75

Rc1/2

70

1X0.35X0.8

LC-XD-040

120

40

101.3

1.1

Rc1 1/4

100

1.3X0.45X0.9

LC-XD-063

160

63

101.3

1.5

Rc1 1/4

140

1.4X0.5X1

LC-XD-100

160

100

101.3

2.2

Rc1 1/2

190

1.5X0.5X1

LC-XD-160

200

160

101.3

4

Rc2

270

1.5X0.75X1.4

LC-XD-200

200

200

101.3

5.5

Rc2

320

1.5X0.75X1.4

LC-XD-250

240

250

101.3

5.5

Rc2

400

1.5X1X1.4

LC-XD-300

240

300

101.3

7.5

Rc2

420

1.5X1X1.4

-

Any composite or fiberglass part that is made using the open mold process can be vacuum infused (refer to the Fiberglass Design Guide for more information on the open mold process).

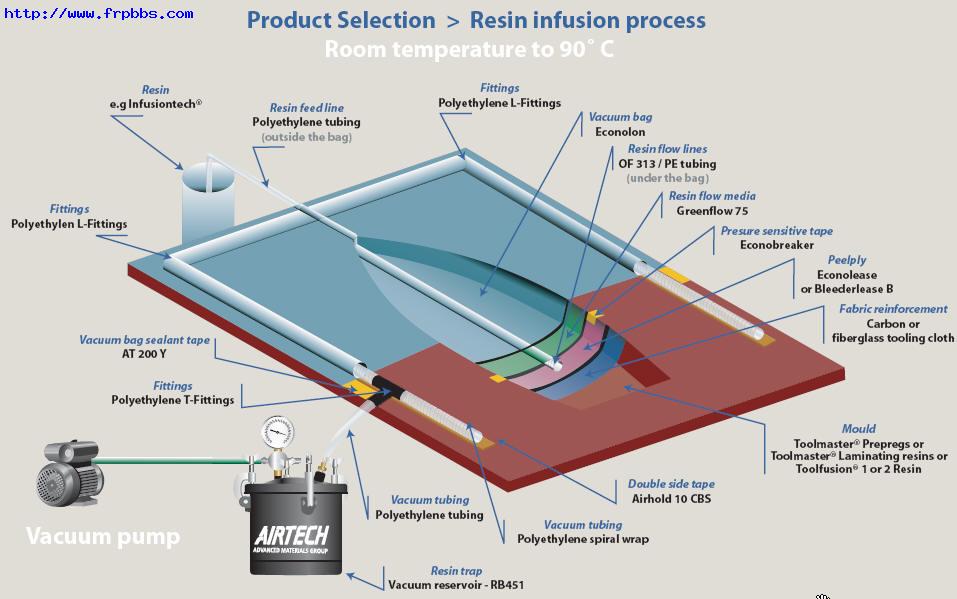

A) Standard fiberglass molds will work for the process if the molds have vacuum integrity and have enough flange width to seal the vacuum bag. The part is typically gel coated in the mold similar to the open mold process.

B) Then the dry reinforcements (fiberglass, carbon, Kevlar etc), core (balsa, or foam), and ribs are precut and placed on to the mold dry.

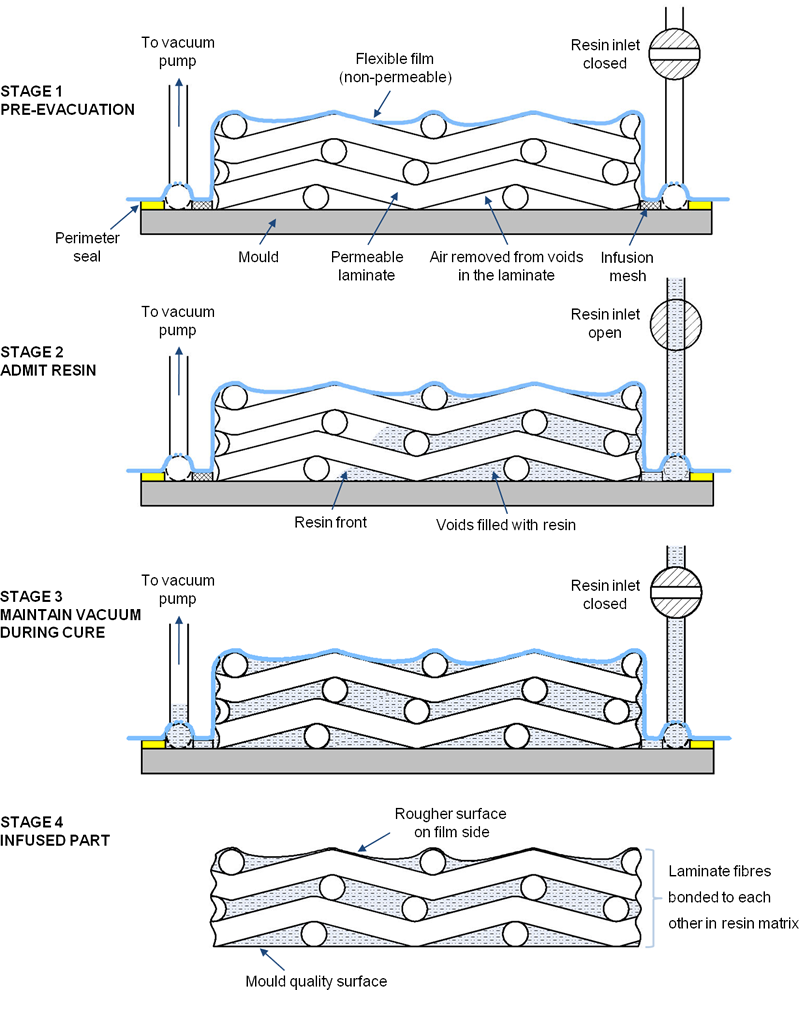

C) After the materials have been loaded, a vacuum bag or an inner mold is placed over the material and sealed against the mold.

D) High vacuum (25 in Hg or more) is used to evacuate the air from the part and resin (polyester, vinyl ester or epoxy) is pulled into the part by the vacuum.

Note: The process is very simple in concept; however, it requires detailed planning and design so the parts can be infused in a reasonable amount of time without any dry spots.The rate of infusion depends on the viscosity of the resin, the distance the resin has to flow, the permeability of the media, and the amount of vacuum.

Conclusion:Therefore, the choice of materials, flow media, resin flow layout, and location of vacuum ports are critical in making good parts.

Message Sent

Thank you for your message, we will be in touch very shortly.

Sorry, there has been a problem and your message was not sent.

If you have any question,please enter your contact details below ! We will contact you as soon as possible !