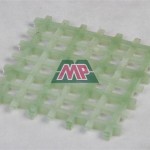

FRP Grating Machine Molds

Each grating mould includes: Mold Cavity, Ejector pin de-molding system, Heating system and the base.

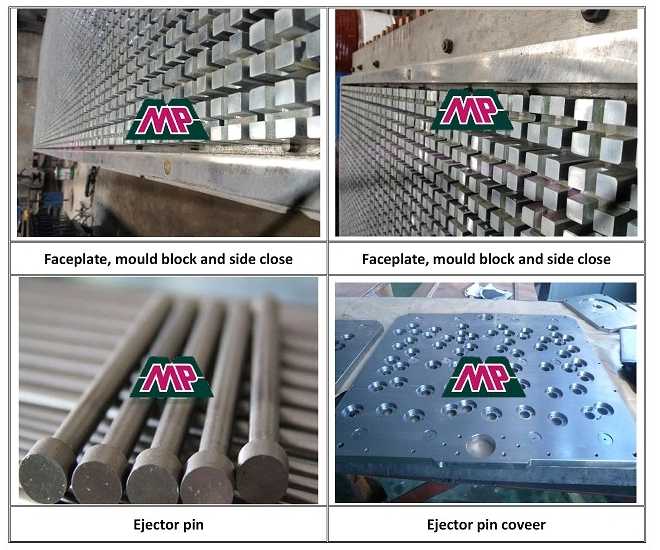

1) Mold Cavity: mold cavity is the core part of the whole mould;it is composed of faceplate, mould block and side close.

a. Faceplate: it is the most important part of the mould. The flatness and finish can decide the quality of the grating.

b. Blocks: the small blocks are made of 45# steel, and chrome finish.

c. Side close: The grating size can be changed by moving this part.

2) Ejector pin de-molding system:

composed of ejector pin, ejector pin cover and support frame.

a. Ejector pin:made of high quality alloy steel (hardness HRC52-53 under 500~600°C),it has good scurf resistance.

b. Ejector pin cover:it made of high quality alloy steel used for guiding the pins.

c. Support frame:I-Type frame is the fixing system for the ejector pins, it has excellent bearing capacity .

3) Heating system (interior heating):

The heating system is the essential system of grating molding. The polyester resin could be cured/hard after heating. This heating system is composed of electric heating tube and connecting system (which connects the inner heating system with exterior heating system)

4) The Base:welded by 16# Channel steel and other steel profiles.

The base guarantees the straight shape of finish grating and also keeps protection support for machine producing, transportation and installation

-

Reference regular gating mould size:

Thickness (mm)

Max. Grating whole panel size(mm)

Center distance(mm)

Gap width(mm)

Grating thickness

Mould thickness

A1×A2

B1

B2

25.4

30

38.1

40

50.8

26.5

32

39

42

52

1007×2007

40×40

7

5

1007×3007

7

5

1007×4007

7

5

1220×3660

38.1×38.1

7

5

1220×3660

38.1×38.1/19×19

7

5

1220×3660

50.8×50.8

8

5

-

Message Sent

Thank you for your message, we will be in touch very shortly.

Sorry, there has been a problem and your message was not sent.

If you have any question,please enter your contact details below ! We will contact you as soon as possible !